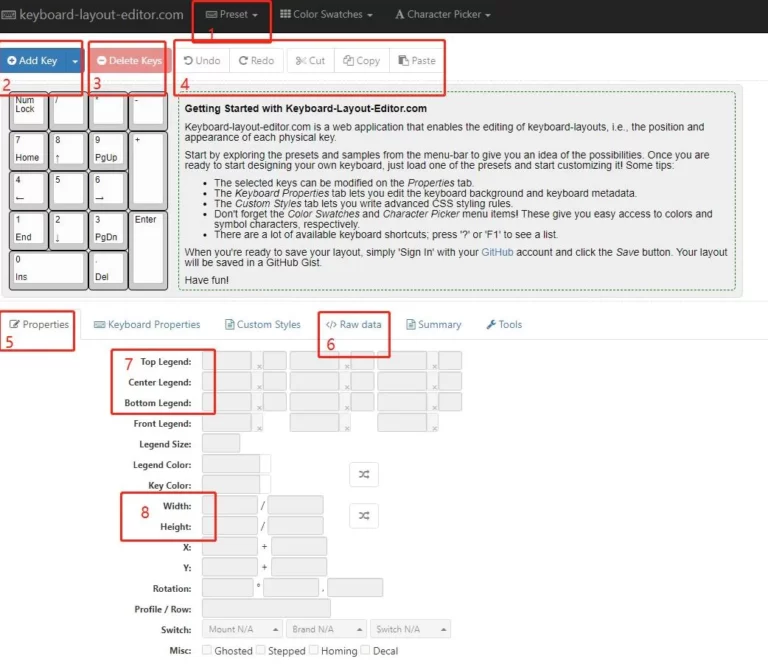

Through our previous article how to make a custom keyboard (一), I believe that you already have your own custom layout keyboard, then we need to generate positioning boards to make shells and PCB plates.

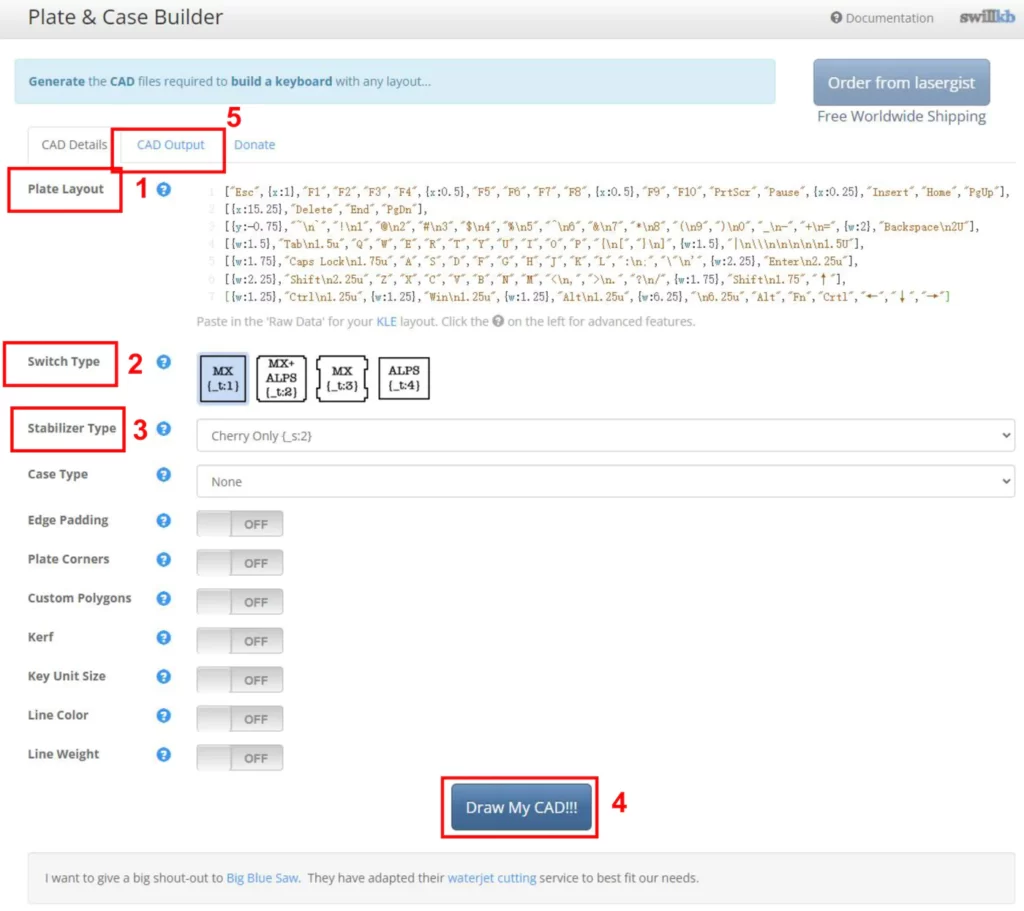

custom keyboard plates tool: Plate & Case Builder

http://builder.swillkb.com In this website, we can generate our keyboard positioning board, the interface is as follows:

Custom keyboard plates tool function description:

1 Plate Layout Your positioning plate layout, copy the column code generated on the KEYBORAD EDITOR website here

2 Switch Type: the type of the switch of the shaft body, select the MX shaft

3 Stabilizer Type: Satellite axis type, here select Cherry Only

4 Draw My CAD: After completing the above 3 steps, click this directly, and the page will automatically jump to

5.In the CAD Output column, as shown in the figure below:

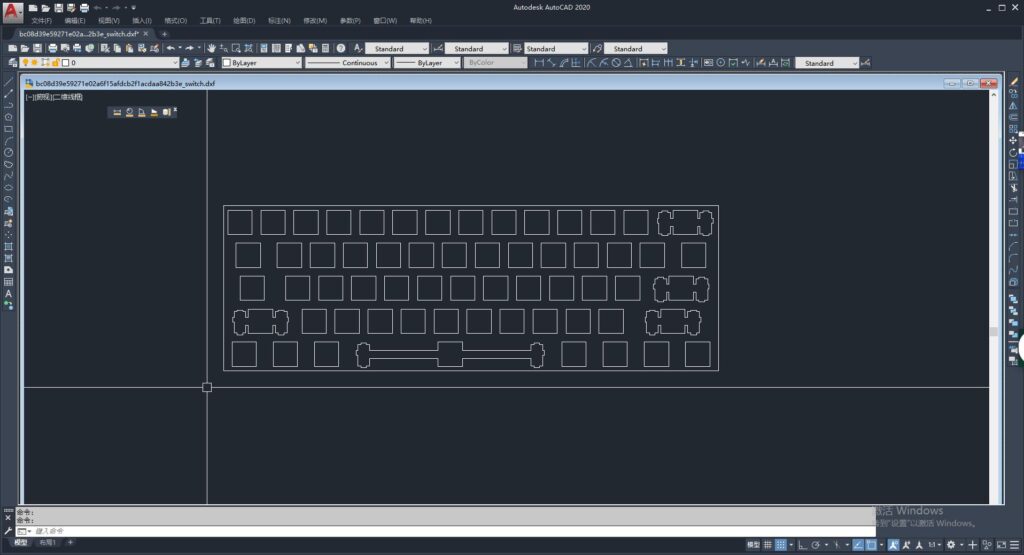

The keyboard positioning board is generated. Here is a brief explanation. The three buttons on the upper right corner of the positioning board can download files in SVG format, DXF format, and EPS format.

There are two important numbers below the positioning board, which are the width and height of your positioning board, and the unit of size is mm

Next we click the DXF button, the downloaded file is saved, and then we need to open it with CAD software.

Open this file with CAD

Using CAD to draw the positioning board, the positioning board is basically drawn, and I also put my own LOGO on the right side of the positioning board

I made 4 protruding fixing structures on the top and bottom of the positioning plate, because it is a TOP MOUNT structure, the positioning plate needs to be fixed with the upper case, so I made holes for M2 screws on the fixing structure.

Basically the positioning plate has been completed, measure the size of the shaft hole, it is 14mmX14mm

After the positioning board of the keyboard is completed, it can be produced directly. Commonly used materials: PC, aluminum, brass, FR4. The processing methods are usually CNC and laser cutting.