From Prototyping to Production

Custom CNC machining services in China

Flexible CNC manufacturing from single custom parts to mass production. Our technical team supports full-process service, solves machining challenges, and provides worry-free cooperation.

Our Experience In Numbers

Trusted CNC Machining Manufacturer in China

We are more than just a manufacturer—we are a trusted partner you can rely on. With years of industry experience and technical expertise, we provide high-quality CNC machining services to clients around the world, helping bring every project to successful completion.

812+

Successfully Project Finished

15+

Years of experience with proud

10,000+

Customers Worldwide

30+

Countries & Regions Served

Manufacturing Services

Our Areas Of Expertise

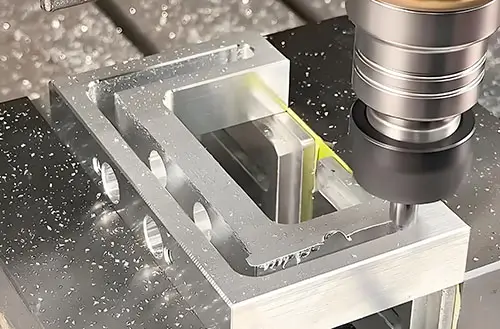

CNC Milling

High-precision multi-axis milling for complex geometries and tight tolerances. We machine a wide range of materials to deliver consistent quality for prototyping and production.

CNC Tuning

Efficient precision turning for cylindrical components with tight tolerances. Our CNC lathes handle diverse materials and complex profiles, ensuring reliable performance for both prototyping and high-volume production.

5-Axis CNC Machining

Advanced 5-axis machining for complex geometries and ultra-tight tolerances in a single setup. Ideal for intricate aerospace, medical, and automotive components, reducing lead times while ensuring superior surface finish and precision.

Swiss-type Machining

Precision machining for complex, small-diameter components. Ideal for medical, electronics, and automotive applications with multi-axis capabilities and strict quality control.

Surface Finishing

Enhance part durability and appearance with expert finishing services—including anodizing, plating, and polishing—tailored to your exact specifications.

Assembly Services

Precision assembly of complex components with strict adherence to specifications and functional testing. We ensure seamless integration and reliable performance for both prototype builds and full-scale production runs.

On - site facilities

Xinrico’s CNC Machine Shops

Xinrico is located in Xiamen, China, covering an area of 4,000 square meters, and is equipped with over 40 sets of CNC machining centers, CNC lathes, and related auxiliary equipment.

CNC milling workshop

CNC Turning Workshop

Anodizing Workshop

Appearance Workshop

Advantages

Why Chose Us?

Expert Engineers

Our team possesses extensive experience and expertise, offering Design for Manufacturability (DFM) feedback and material selection recommendations.

High Quality Parts

Leveraging our ISO certification, we manufacture components with precision CNC technology and verify them through rigorous testing, guaranteeing reliability and stability.

Rapid Lead Time

Backed by our local workshop and reliable partner suppliers, we offer responsive CNC machining services that can meet urgent needs with delivery in as fast as one day.

industry

Historical Examples

Custom keyboard

lightsaber hilt

Automated equipment

Robotics

Testimonials

Whar Our Clients Say

P***d

United States

Good comunication and understanding of part requirements. Hit or exceeded tolerancing on all parts, great packaging for shipment. We will be using their services again!

S***v

Australia

Excellent supplier! The cnc parts were manufactured exactly to our specifications with great precision and high-quality finish. Communication was prompt and professional throughout the process. Shipping was fast and packaging secure.

C***g

South Korea

Highest quality cnc precise with flawless finished. Shipped on time. Highly recommend. Will be using them for all our future cnc anodizing needs.

A***n

Germany

The machining accuracy of the custom parts exceeded our expectations. This factory can handle complex designs and operates at a fast pace, significantly shortening our project timeline

Request a Quote

Ready to Work Together? Build a project with us!

Learn More From

Frequently Asked Questions

Yes, we can make measurements based on your samples to make drawings for machining parts making.

Usually, base on your design drawings or original samples, we give some technical proposals and a quotation to you, after your agreement, we produce for you

We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress.

Yes, we can sign the NDA before got your drawing.