What is anodizing

The so-called anodizing of aluminum is an electrolytic oxidation process in which the surface of aluminum and aluminum alloys is usually converted into an oxide film, which has protective, decorative and some other functional properties.

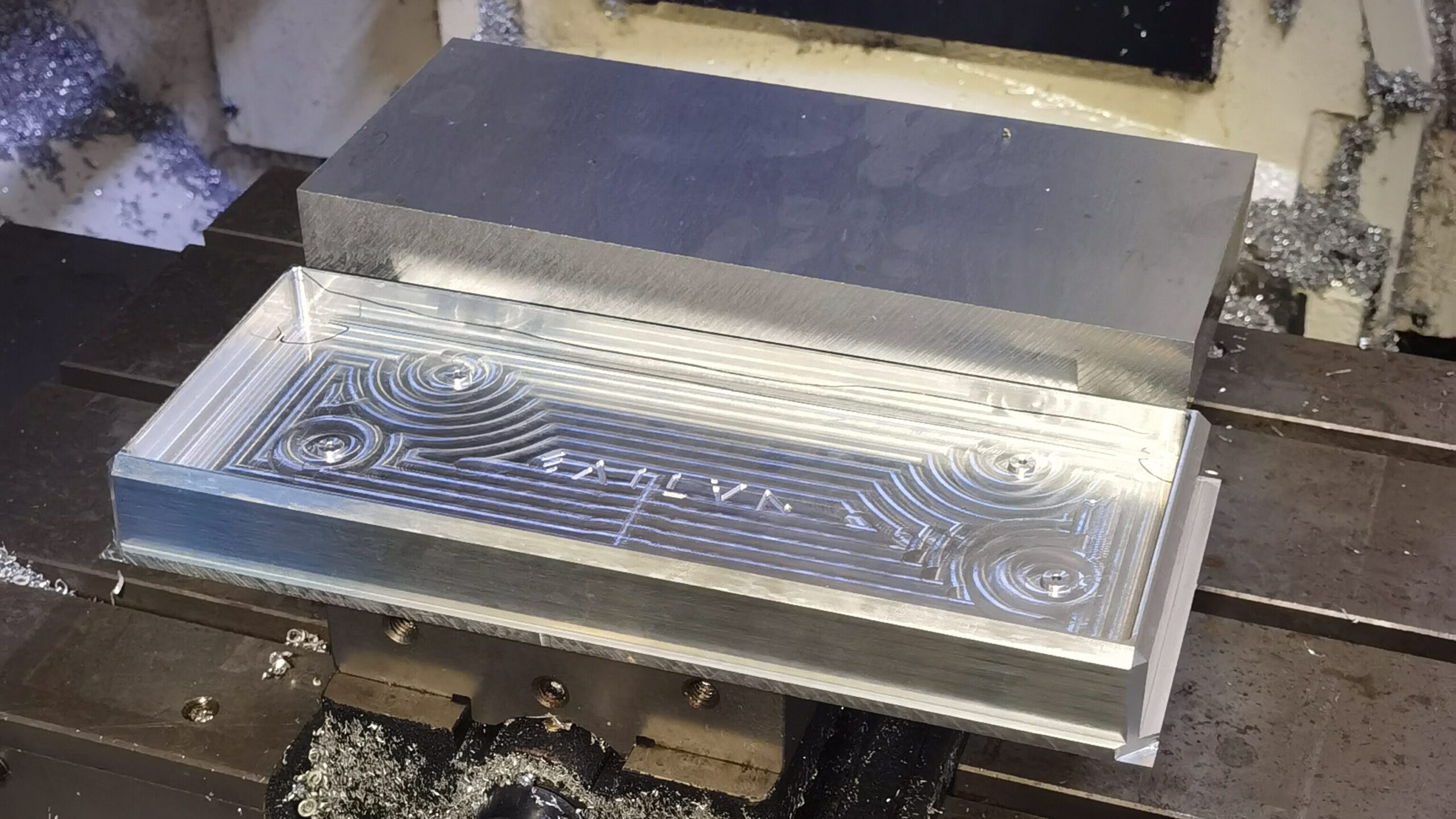

Anodized keyboard process

After the CNC machining of the keyboard shell is completed, it is necessary to inspect the appearance of the parts, such as burrs, rough surfaces, and problems that affect the appearance, which should be resolved before anodizing. Otherwise, after anodizing, it will affect the appearance of the product and cause defective defects. So we should polish it, and usually need to polish off the knife lines on the surface of the shell, steps and other problems that affect the appearance.

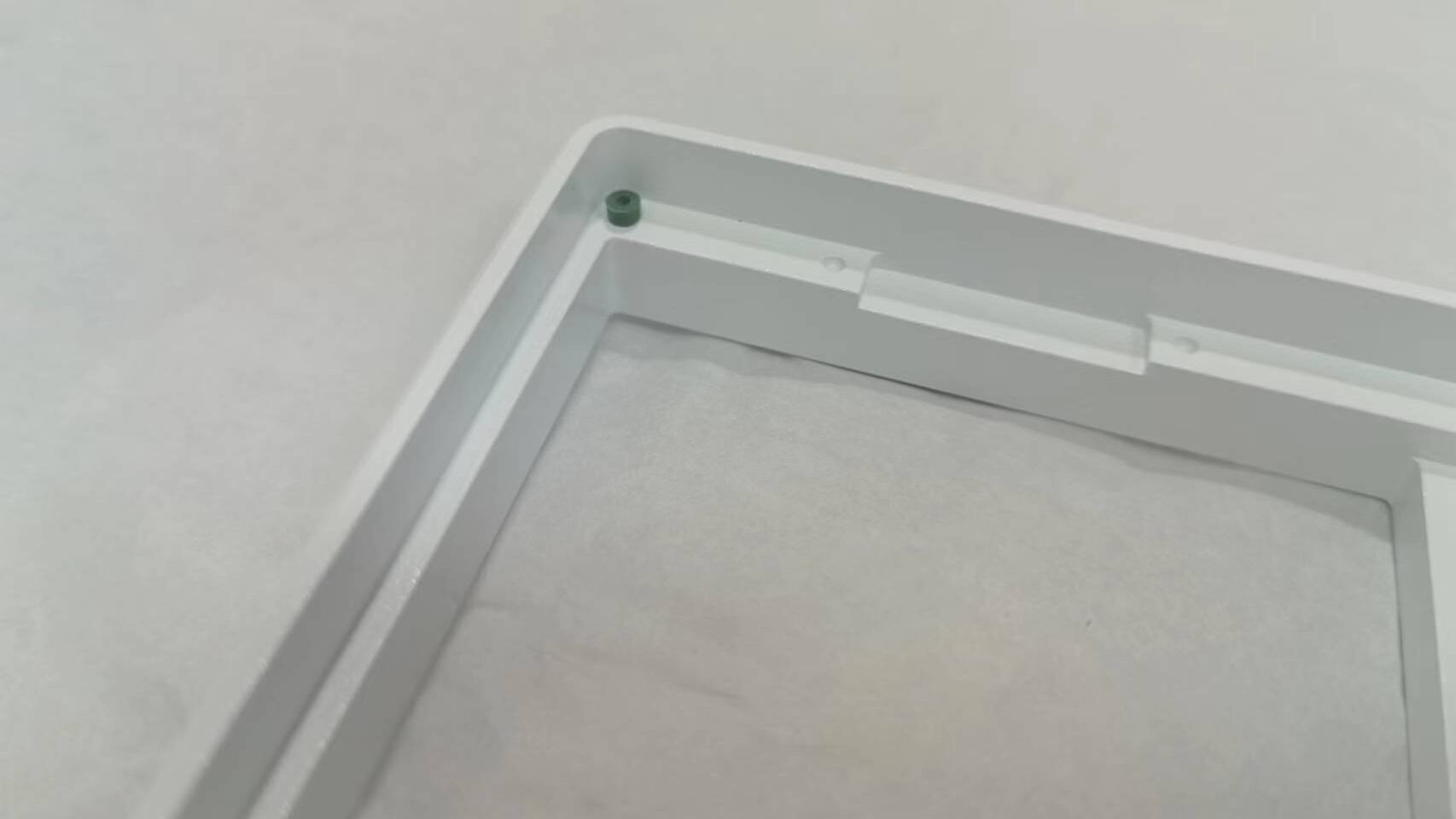

Sealing:

Seal the screw holes to reduce the traces of water flow caused by anodizing.

Sandblasting:

Sandblasting can effectively reduce surface defects. Usually keyboard sandblasting uses 150#, 180#, 200#, 220#. The larger the number of sand models, the finer the surface and the higher the cost.

Keyboard anodized hanger:

In most cases, when the keyboard is in the anode, there will be anodic hanging points, which will cause appearance defects to the product. For this, you can ask the supplier to customize a set of hanging fixtures for you to solve this problem. If your quantity is small , the cost will also be higher, if the quantity is large, it will be the best choice.

In our anodizing workshop, a special hanger is customized for the keyboard, to solve this kind of problem, you don’t need to customize the hanger

Anodized keyboard Color

In addition to white, almost all colors can be done, and it needs to be adjusted by color engineers. Usually the keyboard is black, silver, blue, red, green, purple,

Two-color anode:

Product packaging

For the anodized product, when removing the hanger, be careful that the card of the hanger will scratch the keyboard. After removing it, check the appearance to see if there is no problem, and then pack it into a box.