Customized Keyboard Manufacturer

TRUSTED CUSTOMIZED KEYBOARD MANUFACTURER

Has a series of surface treatment processes: anodizing, PVD, painting, polishing, laser engraving, etc.

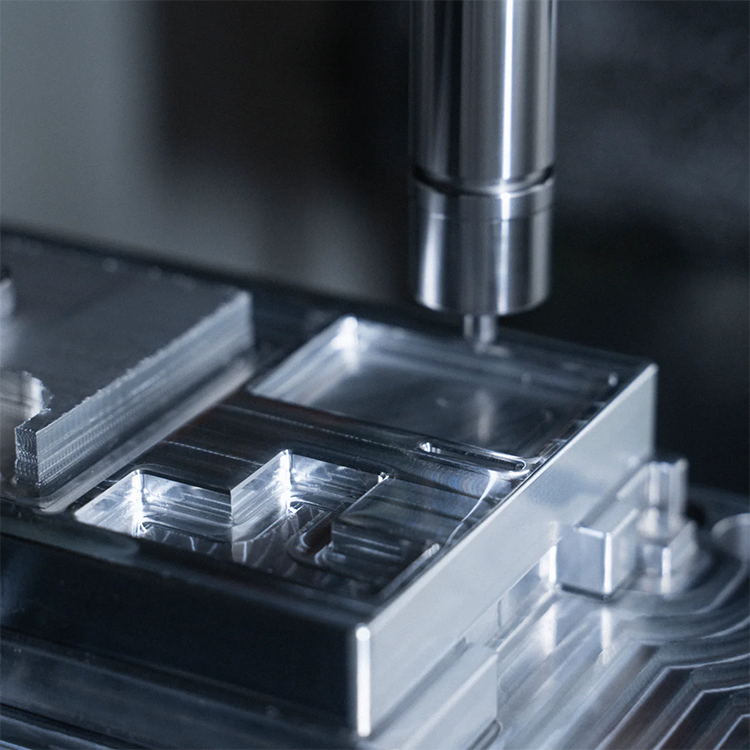

Why Use Xinrico For Custom Keyboard Cnc Machining Services?

Professional Custom keyboard manufacturing industry chain, we have 300+ cooperative suppliers

Our CNC machining machine shop can make any custom design, simple or complex. We provide rapid prototyping, small batch processing and high volume production, all orders are serviced by xinrico from start to finish. Our fast CNC machining capabilities include metal and plastic services as well as flexible production and shipping options to meet your needs at the perfect price and product development stage.

Surface Treatment

From our carefully selected and tested suppliers to complete the top 10 surface treatment processes

Anodizing Process

own workshop

Electrophoresis Process

Strictly select suppliers

Painting Process

Strictly select suppliers

PVD

Strictly select suppliers

CNC Machining Keyboard Project

Provide professional support for keyboard designers, their works are amazing!

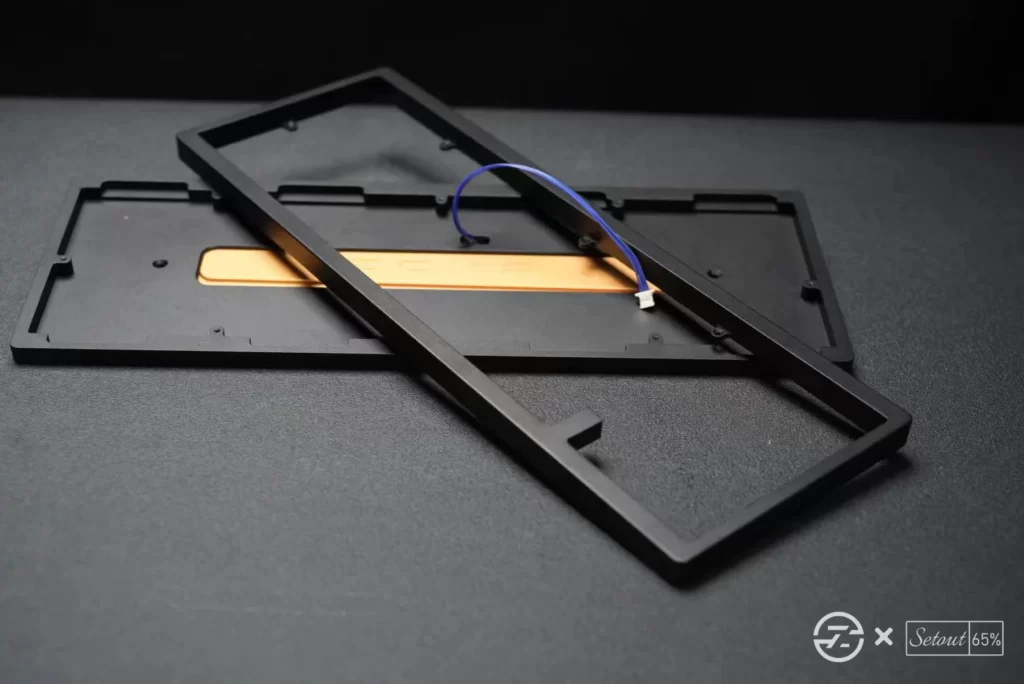

Setout 65

Blue anodized 6063 aluminum sandblasted at 180#, with aluminum/copper weight and a positioning plate of PC/POM/FR4.

MXRSKEY Y80 TK

6063 national standard aluminum CNC processing, anodic oxidation / electrophoresis.

HANG 98

Sandblasted 6063 aluminum, anodized with multiple colors, copper counterweight PVD, UV nameplate, and CNC copper positioning plate.

Pad+Alice=Palice

Adopting 6063 aluminum material, with sandblasting of 150#, black anodizing and electrophoresis in white.

Why Choose Us

We focus on customized keyboard OEM, we serve customers on zfrontier in China, and have gained a good reputation.

Experience

Our experienced engineers can handle your custom keyboard CNC machining project with ease.

Surface Treatment

Advanced Equipment

MOQ

Quality Professionals

Delivery Date

We have a strong supply chain to deliver your products on time and in quantity

10000+

Number Of Keyboards

100+

Keyboard Style

20+

Surface treatment process

200+

Customers served

10yr

Manufacturing experience

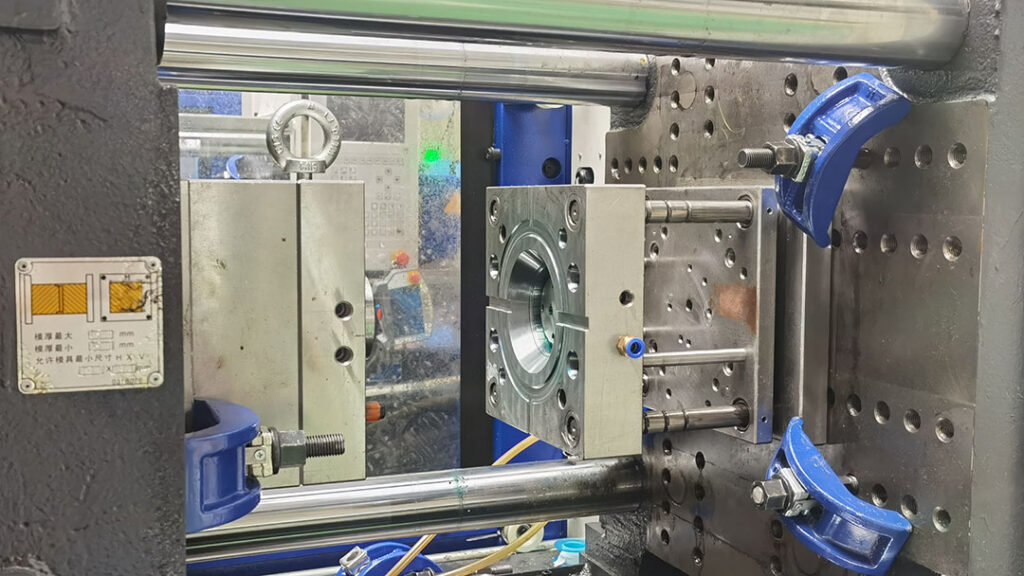

We have our own CNC machining, injection molding, anodizing in-house production workshop

Surface Finishes for CNC Machining

CNC machining leaves visible tool marks during the process of removing portions of the block’s surface to create desired shapes. If don’t want as-machined parts, select a surface finishing for your custom parts. At Xinrico, we offer several common surface finishes that help improve functionality and aesthetics.

Bead Blasting

Bead blasting results in parts with a smooth surface with a matte texture. Used mainly for visual applications and can be followed by other surface treatments.

Powder Coating

Powder coating is a surface treatment process that involves applying dry powder to materials such as metal or plastic, then heating to fuse the powder particles and create a smooth, durable coating. The process can be used to apply a variety of colors, textures and finishes to the surface of the material.

Electroplating

The electroplating process involves several steps, including cleaning and preparing the substrate surface, coating it with a conductive material, immersing the substrate in an electrolyte solution, and applying an electrical current to deposit metal ions onto the substrate surface. The resulting metal layer can be polished, textured or colored to achieve a variety of finishes.

Polishing

Involves smoothing and shining the surface of a material such as metal, plastic or glass to improve its appearance, texture and reflectivity. The process involves the use of abrasive materials, such as polishing compounds or diamond grit, to remove small imperfections and scratches from the surface of the material, resulting in a smooth and shiny finish.

Plastics

Create a line pattern on the surface of a material such as metal with an abrasive belt or abrasive pad. This process is often used to create a decorative finish on metal surfaces or to remove small imperfections and scratches.

CNC Turning Materials

A numebr of materials can be used in CNC Turning , giving you various of options to complete rapid prototyping to production runs of custom complex parts. For your manufacturing needs, we provide instant quotatios of 100+ metals and plastics, and even you can compare prices for different machining materials.

Aluminum

Aluminum is a lightweight, silver-white metal with a low density, which makes it lightweight and easy to machine.

Copper

Copper displays excellent thermal conductivity, electrical conductivity and plasticity. It is also highly ductile, corrosion resistant and can be easily welded.

Brass

Brass has desirable properties for a number of applications. It is low friction, has excellent electrical conductivity and has a golden (brass) appearance.

Stainless Steel

Stainless steel is an alloy steel containing at least 10.5% chromium by mass. High corrosion resistance, durability and strength. It can be made in different shapes and sizes through various processes such as casting, forging and welding.

Titanium

Titanium is a silvery metal known for its high strength, low density and excellent corrosion resistance. Titanium is used in a wide variety of industries including aerospace, medical, automotive and sports equipment. Its high strength-to-weight ratio makes it ideal for applications where strength and durability are critical, but weight must be kept to a minimum.

Plastics

Plastics are also very popular option for CNC machining because of its wide choices, relatively lower price, and significantly faster machining time needed. We provide all common plastics for CNC machining services.

| POM | PEEK | HDPE | PET |

| Nylon | PTFE | PVC | PP |

| ABS | PC | PMMA |