Many players have higher and higher requirements for keyboards, and even need a mechanical keyboard that suits them in all directions. How can they suit themselves in all directions? So there is a customized keyboard. Giving those who are serious about their keyboards the opportunity to create their own.

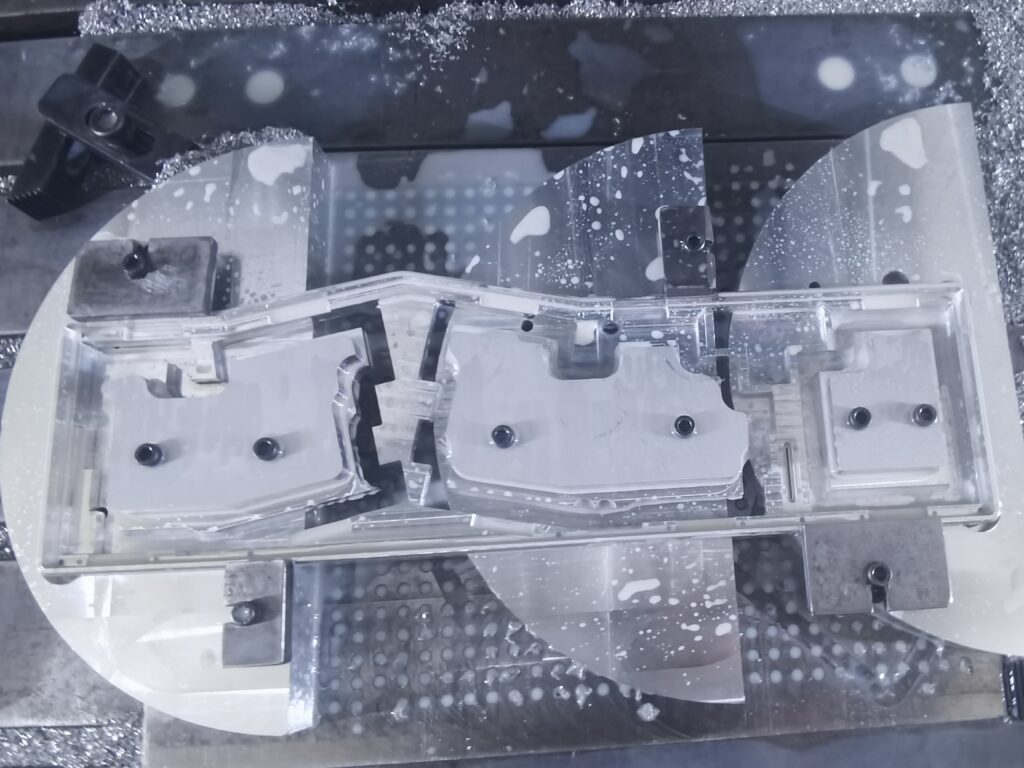

Usually these whimsical designs are basically realized through CNC machining. No matter who you are, as long as you have your own ideas, you can make prototypes or share your designs with more like-minded people.

Once you’ve designed your own keyboard, there are many benefits to using a milled keyboard, including personal customization options, materials, colors, and more. If you have an idea, you may wish to contact us to make your design a reality, we are very experienced in making keyboards, and hope to help you.

What is a CNC keyboard?

The CNC keyboard is a keyboard manufactured by numerical control processing technology, and the casing of the keyboard is usually made of metal materials, such as aluminum, brass, and stainless steel. The keycaps and casing of the keyboard are usually machined using CNC.

CNC keyboards are often preferred by hobbyists and professionals who want a keyboard that offers a high level of performance and customization. However, they are usually more expensive than traditional keyboards due to the cost of the machining process and the high-quality materials used.

Why use a CNC keyboard?

Usually everyone uses mass-produced plastic keyboards. For programmers, editors, etc. who have specific needs, they need to customize. CNC keyboards are usually known for their high-quality manufacturing, precision and durability. They’re also highly customizable, with many options for different keycap styles, colors, and layouts. Some CNC keyboards also have programmable keys, allowing users to customize the function of each key according to their own habits.

Why choose CNC machining keyboard?

Aesthetics

The keyboard casing is usually finished by aluminum CNC processing, and after surface treatment such as anodizing, spraying, electrophoresis, etc., the casing has better scratch resistance, and a variety of colors are available to enhance the aesthetics of the keyboard. Just like all kinds of electronic products on the market, there can be more choices.

durability

The keyboard is made of aluminum, copper, stainless steel, titanium alloy and other materials, which is more durable than the plastic keyboard on the market.

Economy

Custom keyboard shells are usually made of aluminum. If you only want to do one piece of testing in the early stage, you can choose 3D printing for structural testing. CNC machining is used for final manufacturing because of its higher precision.

Due to the large number of plastic keyboards, injection molding is the most economical method, and custom molds are required to complete. For smaller quantities, CNC machining costs are much lower.

Environmental protection

Keyboard casings made of aluminum are easy to recycle. So don’t worry about the environmental hazards they may cause because aluminum can be easily recycled.

CNC keyboard case material selection

There are many materials for manufacturing keyboard casings, each of which has unique advantages. Usually, CNC keyboard casings are made of aluminum. Let’s take a look at the different materials.

aluminum material

The shells of most electronic products are made of aluminum, and customized keyboards are no exception. The aluminum models include the following commonly used ones:

Aluminum 6061

This form of aluminum alloy is considered the best for its combination of strength, corrosion resistance and good surface finish when manufacturing keypads, and is often the first choice for spray electrophoretic finishes.

Aluminum 6063

Similar in properties to aluminum 6061, it is a good choice for anodizing keyboard casings due to its stable finish.

Aluminum 5052

5052 aluminum for perfect finish and corrosion resistance of the keyboard. However, although machining is somewhat difficult, heat treatment cannot be performed.

Other less common useful alloys include 5053, 6053 and 7075. Most of these are not available as options for CNC keypad enclosures.

copper material

Copper provides corrosion resistance, durability, aesthetic appearance and workability. It is often used on counterweights and nameplates. It is anti-oxidation through sandblasting and sealing oil. After polishing and electroplating, it looks very beautiful. It is a very good choice for CNC keyboard.

Stainless steel

Stainless steel has corrosion resistance, unique rust and stain resistance, and is strong, durable and easy to clean, making it the first choice for keyboard weights. After polishing PVD, the decoration is great.

titanium

Titanium is another material that can be used for keyboard machined casings. Titanium is sometimes preferred because of its inertness. Therefore, they are highly corrosion resistant. They also offer an impressive finish.

CNC keyboard manufacturing process

From design to programming CNC machining, post-processing, surface treatment, quality inspection, packaging, our professional manufacturing process.

audit programming

When we receive your design file (step), we need to review the keyboard shell. According to our experience, check whether there is any unreasonable situation, and then proceed to CNC programming after it is correct.

CNC Machining

After all the designs are checked and correct, choose a 3-axis or 4-axis CNC machining center for machining. At this time, the upper and lower covers of the keyboard and other parts will be completed here.

Post-processing

Deburring

After the keyboard shell is added, there will be some burrs. Use corresponding tools to remove these burrs to make the shell more complete.

polishing

After CNC processing is completed, there will be flaws such as knife lines on the surface, and polishing tools are used to polish these flaws. It is very helpful for surface preparation.

CNC machining keyboard surface treatment

Anodizing

Anodizing creates a hard, durable, and corrosion-resistant surface that can be dyed in a variety of colors, making it an excellent choice for CNC keypads.

Electrophoresis

With the advantages of uniformity, smoothness and smoothness, the hardness, adhesion, corrosion resistance, impact performance and permeability of the electrophoretic paint film are obviously superior to other coating processes. And the colors are also diverse