For aerospace CNC machining, precision and accuracy are key. CNC machine tools are used to manufacture a wide variety of aerospace components, from engine parts to landing gear to avionics systems.

To ensure the highest level of quality, aerospace designers must have an in-depth understanding of the materials and processes involved in aerospace manufacturing. From titanium alloys to composite materials, aerospace CNC machining requires the highest level of expertise and attention to detail.

What is Aerospace CNC Machining?

Aerospace components operate under harsh conditions for long periods of time and must therefore be manufactured with extreme precision. In aerospace applications, the smallest flaw can lead to component and system failure. CNC machining reduces the possibility of human error by automating the manufacturing process. It also allows aerospace machine shops to produce parts at higher speeds, with greater precision and repeatability than traditional machining processes.

CNC machining/turning technology can improve the accuracy and precision of aerospace products, reduce or minimize manufacturing errors, and make CNC aircraft parts of higher quality and durability.

The Importance of Precision in the Aerospace Industry

Accuracy and precision are critical. Aerospace parts are exposed to extreme conditions and forces, so they require extremely tight tolerances and finishes, often measured in thousandths of an inch. CNC machining can achieve this level of precision.

Precision Machining for the Aerospace Industry

Unlike other industries, the aerospace industry requires the exacting and highest possible dimensions, tolerances and performance of each part. This is to ensure that these parts do not fail in flight. CNC machines can produce identical parts with consistent quality, reducing the risk of errors and variations in the manufacturing process.

Aerospace CNC Machining Applications

CNC machining is used in many industries. An airplane has millions of parts. Therefore, its production involves many manufacturing processes. Engine parts, landing gear, wings, fuselage parts and other aircraft parts. CNC machining produces parts with tight tolerances, complex geometries and high surface finishes.

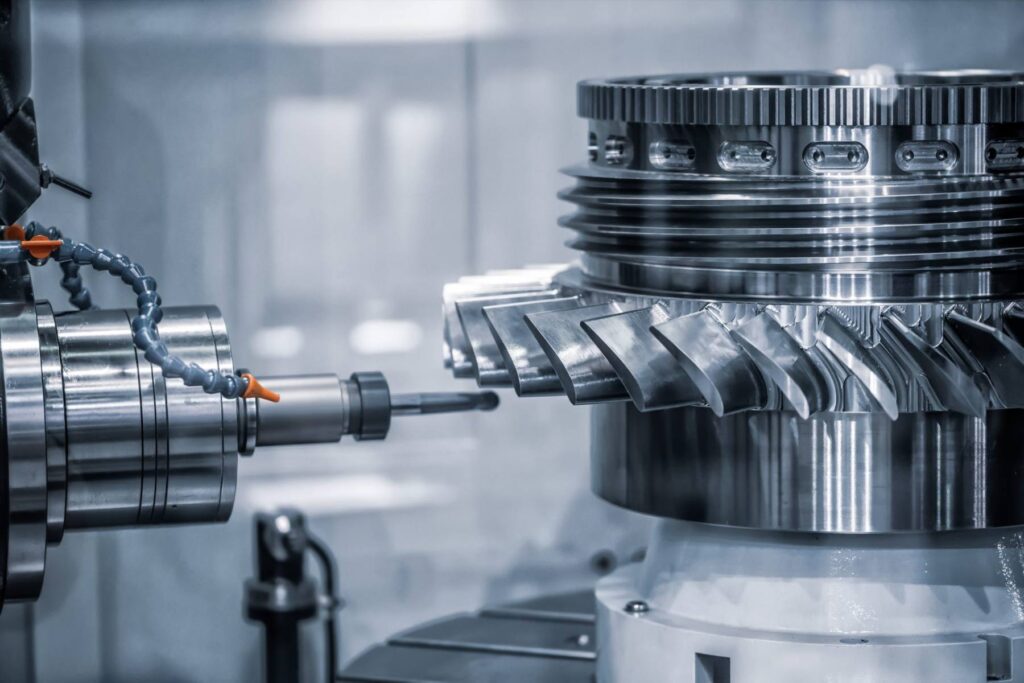

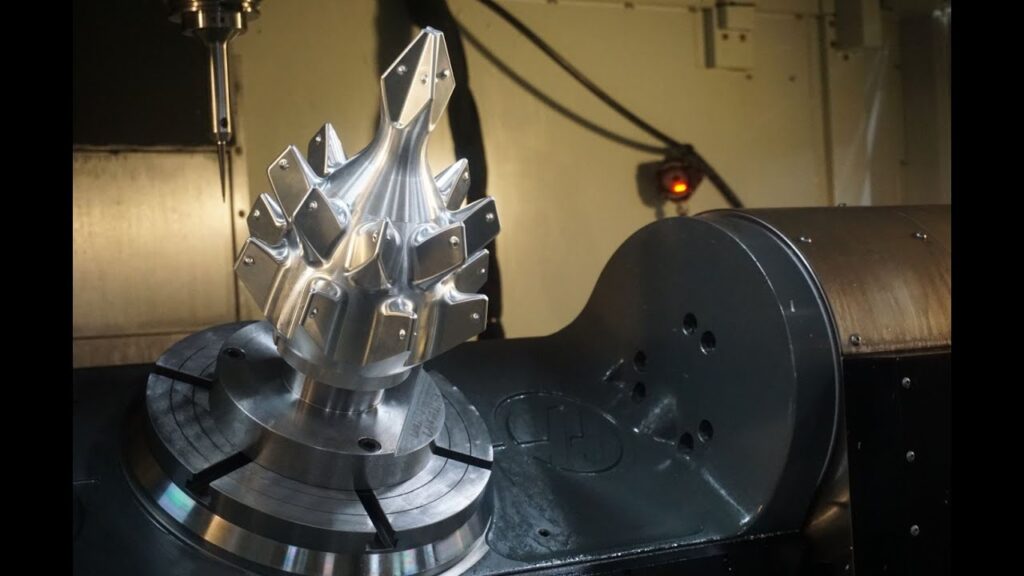

5-axis CNC aerospace machining

The 5-axis machine tool has very obvious advantages for the processing of complex parts, reducing more settings of the workpiece, higher precision, better surface finish, reduced cost and operation time, and is the first choice for processing aerospace parts.

Aerospace parts are often complex and diverse, requiring high strength-to-weight ratios and tight tolerances. 5-axis CNC can do these jobs well because of its excellent precision and efficiency.

Aerospace Material Selection

The aerospace industry has a huge demand for machined parts. Materials need to meet extreme conditions such as high strength, high temperature, and high corrosion resistance.

High performance lightweight metal

The use of lightweight materials in aerospace can reduce structural weight, increase payload, and reduce aircraft fuel consumption and other energy consumption. The high performance and lightweight of aerospace materials is a never-ending research.

Titanium alloy: high strength to weight ratio, about 30% stronger than steel, 50% lighter, excellent corrosion resistance and high temperature performance, is one of the most commonly used materials in the aerospace industry. They are commonly used to make engine components, airframe structures and flight control components.

Superalloys: Often used to make engine components because they can withstand high temperatures and pressures. These materials have good high temperature stability and corrosion resistance, such as nickel-based alloys and cobalt-based alloys.

Carbon fiber composite materials: have the advantages of light weight and high strength, and are usually used to manufacture structural components in the aerospace industry, such as wings and empennages.

Aluminum alloy: A lightweight, high-strength, corrosion-resistant material commonly used to manufacture aircraft skins and internal structural components.

Copper alloy: Excellent electrical and thermal conductivity, often used in the manufacture of electronic equipment and instruments.

high performance plastics

Although metal components have more applications in the functional structure of aircraft, many interior components are derived from polymer materials. These materials are much lighter than metal. They help produce interior wall panels, ventilation ducts, aircraft doors, wiring ducts, bearings and more. They are aerospace-grade plastic that is lightweight, strong, and meets aerospace flammability regulations.

Aerospace CNC machining creates strong, lightweight and complex plastic parts for the aerospace industry. Materials such as PEEK and other high-performance polymers are used to manufacture these parts. Similar to metal machining, aerospace machining provides the high precision required for polymer-based aerospace applications.