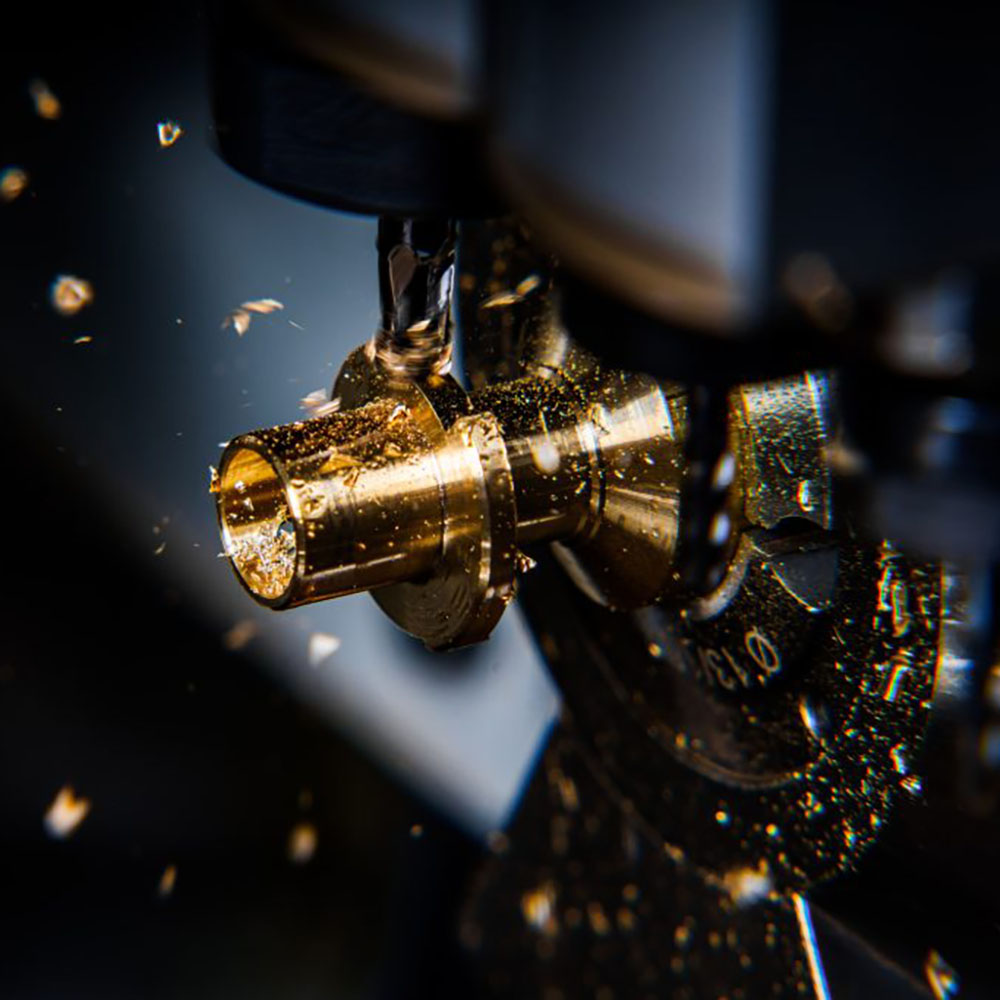

Ultimate Guide for Brass CNC Machining

china brass cnc machining manufacturer

Brass is a specialized copper alloy that is used in a variety of machining applications and has been for a long time. Due to the unique advantages it offers, it has become a popular machined material in the component manufacturing industry due to its excellent thermal and electrical conductivity, corrosion resistance and aesthetics.

In this guide, we will give you the ultimate guide to brass CNC machining, including the basics of the process, the pros and cons, the types of brass alloys used for machining, and factors to consider when choosing a brass CNC machining service provider.

Brass CNC Machining Basics

Brass CNC machining involves the use of CNC machines to cut and form brass parts and assemblies to precise specifications. The process starts with a 3D model of the part or assembly, which is programmed into the computer of the CNC machine. A CNC machine then uses a range of cutting tools, including drills, end mills and lathes, to remove material from the brass block until the desired shape is achieved.

Advantages and Disadvantages of Brass CNC Machining

advantage:

- Precision: Brass CNC machining can produce parts with very tight tolerances, typically within a few thousandths of an inch.

- Consistency: CNC machines can produce identical parts with high precision and repeatability, ensuring consistency in mass production runs.

- Versatility: CNC machines can produce a wide variety of complex shapes and features, including threads, pockets, and cavities.

- Surface finish: CNC machines can produce high-quality surface finishes on brass parts, reducing the need for additional finishing processes.

shortcoming:

- Cost: CNC machining can be expensive, especially for small batches.

- Material limitations: CNC machines may not be suitable for all brass alloys, and some alloys may require specialized cutting tools or processes.

- Design limitations: Depending on the capabilities of the machine, CNC machines may have limitations on the shapes and types of features that can be produced.

Types of Brass Alloys Used for Machining

There are several types of brass alloys commonly used in CNC machining, including:

- C36000, also known as free-cutting brass, is a leaded brass alloy that is easy to machine and has excellent cutting properties. It is often used in high speed machining applications such as screw machine parts and accessories.

- C46400, also known as Navy Brass, is a high-strength brass alloy that is corrosion-resistant and wear-resistant. It is commonly used in marine hardware, valve stems and pump shafts.

- C26000, also known as cartridge brass, is a brass alloy commonly used in cartridge casings, plumbing fittings, and electrical components.

- C28000, also known as Muntz Metal, is a brass alloy commonly used in architectural applications such as trim and hardware.

Finishes and Post-Processing Options

Just as it is machined

One benefit of brass is that it easily accepts machining. Hence, the freshly machined surfaces normally come out looking attractive and pretty. This means you may not need any additional finishes.

Thus, it is possible to leave some parts just as they were machined. However, the surface finish can be enhanced with extra finishing passes.

Hand polishing, honing, and buffing

Brass is an attractive material used for a number of practices. But in most cases, brass is chosen for ornament applications. This is because most brass alloys can show up in various colors.

For a smooth and attractive finish, hand polishing, honing, and buffing is considered. You can polish the brass to create an even and glossy surface making it perfect for aesthetic components.

Factors to consider when choosing a brass CNC processing service provider

When selecting a brass CNC machining service provider, there are several factors to consider, including:

- Experience: Look for a supplier with experience in machining brass components, especially if you have complex or high precision requirements.

- Equipment: Make sure the supplier has modern, high-quality CNC machines and cutting tools capable of producing the parts you need.

- Quality Control: Ask about the supplier’s quality control process, including inspection and testing, to ensure that the parts you receive meet your specifications.

- Lead time: Consider the lead time for suppliers to produce your part, as well as any additional time required for shipping and delivery.

- Cost: Consider the provider’s pricing, including any installation fees, material costs, and shipping costs, to ensure the overall cost is within your budget.

In summary, brass CNC machining is a high-precision and versatile process for producing brass parts and assemblies. By understanding the basics of the process, its advantages and disadvantages, the types of brass alloys used for machining, and factors to consider when selecting a service provider, you can make an informed decision and ensure that you receive high quality that meets your needs Parts required.

At Xinrico, we have plent of material options for CNC machining serivice, If you’d like to partner with us for your next project, contact us today.